Thermostats and Hygrostats. Climate control for electrical panels

The conditions inside an electrical panel must be such as to preserve the reliability of the equipment contained within it. The correct thermal analysis and thermal management of a panel is one of the most important actions for guaranteeing performance and reliability over time, as well as for c...

The conditions inside an electrical panel must be such as to preserve the reliability of the equipment contained within it. The correct thermal analysis and thermal management of a panel is one of the most important actions for guaranteeing performance and reliability over time, as well as for compliance with the relevant regulations.

Overheating and condensation

Excessively high temperatures inside a panel are a cause of degradation of the internal components with consequental deterioration of the system’s performance.

Also the presence of humidity is a risk, being a potential cause of short circuits or leakage currents – resulting in safety issues and power cuts to the equipment.

Considering that installed equipment and machinary, their replacement and even their repair, easily represents costs vastly greater than the cost of a temperature control system, provision of the latter can justify itself many times, over time.

Thermal sizing of electrical panels and the new EN 61349-1 standard for LV switchgear and controlgear assemblies

To guarantee the correct thermal sizing of an electrical panel, several factors must be considered, mainly:

• the environmental conditions of installation and therefore the right degree of IP protection

• the power dissipated by electrical and electronic equipment when operating

• heat radiated from external or internal sources

The temperature rise within an electrical panel is subject to the requirements of EN 61349-1, which provides limits for average over-temperature values and the maximum values of relative humidity – related to air temperature and altitude above sea level, within which the equipment is to operate.

How to control the temperature

In the event that the temperature within the panel is not within acceptable limits, solution(s) must be adopted to correct the situation.

One solution is to use industrial thermoregulation products, such as fans or heating elements, controlled by a Thermostat or a panel Thermo-Hygrostat.

Thermostat or a Thermo-Hygrostat – which is better?

To understand which product best meets your needs, you must first consider if the need is to control just the temperature, or to control humidity and temperature. You then need to consider if this can be achieved by heating management, ventilation activation or humidity measurement and control.

With a thermostat it is possible to manage heating and ventilation within the panel according to the measured temperature.

With a Thermo-Hygrostat we have the additional function of measuring the air humidity, as well as the temperature.

In this way, with a Thermo-Hygrostat working with a heater, it is possible to raise the temperature of the panel and move away from the “dew point”, keeping the humidity level under control and avoiding the risks associated with the formation of condensation.

Finder Thermostats and Thermo-Hygrostats are particularly versatile because of a more compact size (17.5 mm) compared to others on the market, and are available in different versions:

Type 7T.81.0.00.240x, panel Thermostat – heating control

This Thermostat is available in two versions, each with a different temperature control range:

• 0 ° to + 60 ° C

• -20 ° to + 40 ° C

This type of Thermostat generally works in conjunction with a resistance heater – when it is necessary to raise the temperature within the panel

When the panel temperature falls below the set value the contact closes, energizing the heater. The contact then reopens when the temperature rises above this value.

Type 7T.81.0.000.230x, panel thermostat for activating a ventilation system for cooling

This type of Thermostat is generally associated with a ventilation system – when it is necessary to lower the temperature within the panel.

When the panel temperature exceeds the set value, the contact closes, activating the cooling device. The contact then reopens when the temperature drops below this value.

Available in two versions, with adjustment range:

• 0 ° to + 60 ° C

• -20 ° to + 40 ° C

Type 7T.51.0.230.4360, panel Thermo-Hygrostat for humidity and temperature control

This features electronic control for both temperature and humidity, adjustable with two selectors.

The adjustment fields are:

• Temperature: + 10 … + 60 ° C

• Humidity: 50 … 90%

A third selector selects one of 4 functions, HT, TH, HL, HM – and incorporates a back-lit indicator to show when output contact is closed.

Simultaneous humidity and temperature control

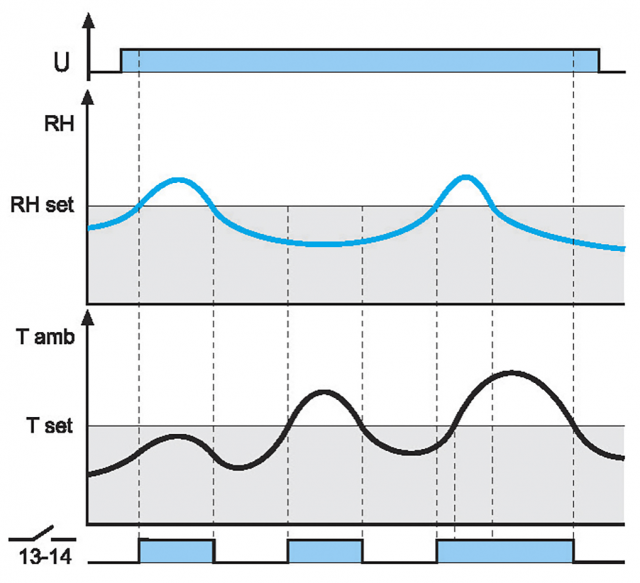

HT: RH > RHset OR Tamb > Tset

The contact closes if the ambient humidity (RH) is > set humidity value (RHset) or if the ambient temperature (Tamb) is > set temperature value (Tset)

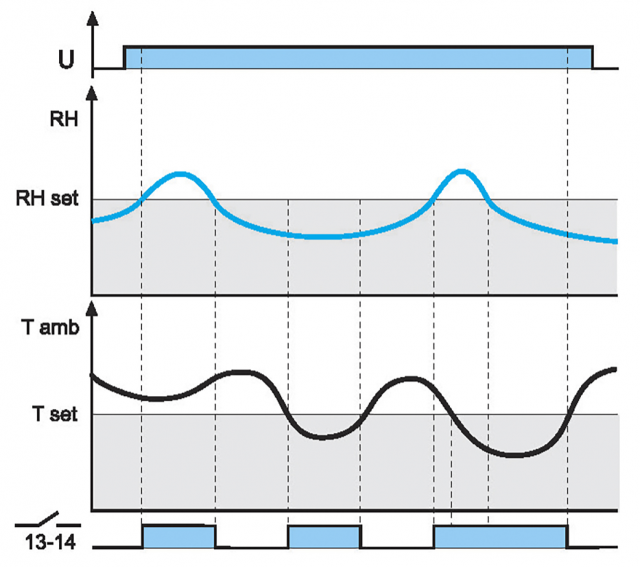

TH: RH > RHset OR Tamb < Tset

The contact closes if the ambient humidity (RH) is > set humidity value (RHset) or if the ambient temperature (Tamb) is < set temperature value (Tset)

Humidity control

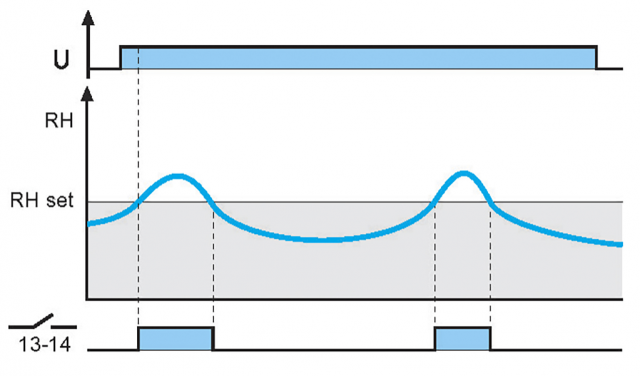

HL: RH < RHset

The contact closes if the ambient humidity (RH) is < set humidity value (RHset).

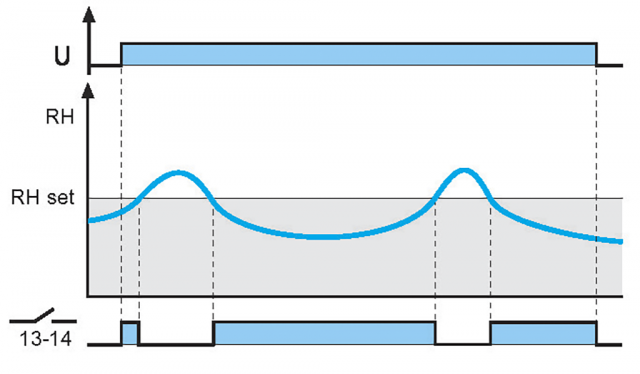

HM: RH > RHset

The contact closes if the ambient humidity (RH) is > set humidity value (RHset).