Boom or no boom that’s the question. Finder’s product range of ATEX / HazLoc certified components is the answer.

HazLoc? ATEX? Class 1 Division 2?

Various terminologies exist globally and understanding what they are and products available is important for correct system design. What you are building; where is it going and what will you use.

HazLoc or hazardous location is an environment where the potential of explosion or fire may exist. The atmosphere always has or could become volatile with gas or vapors to dust and particulates.

ATEX – In Europe ATEX refers to a directive for product used in hazardous locations. The logo is followed by further categories to defined equipment group and available protection for the application’s environment.

Example:

- II 3G Ex ec Ex nC IIC Gc which outlines level of protection, increased safety, sealed device, type of gas, and protection level.

Class and Division Codes – The National Electrical Code (NEC) has their own U.S. version. It properly defines applications into Classes, Divisions and Groups. This consists of 3 classes, 2 divisions and 7 groups.

- Example: Class 1 Division 2 Groups A, B, C & D T5. This defines material type, likelihood of presence, material properties and often temperature class.

What is offered to designers for these environments? Finder rises to the challenge.

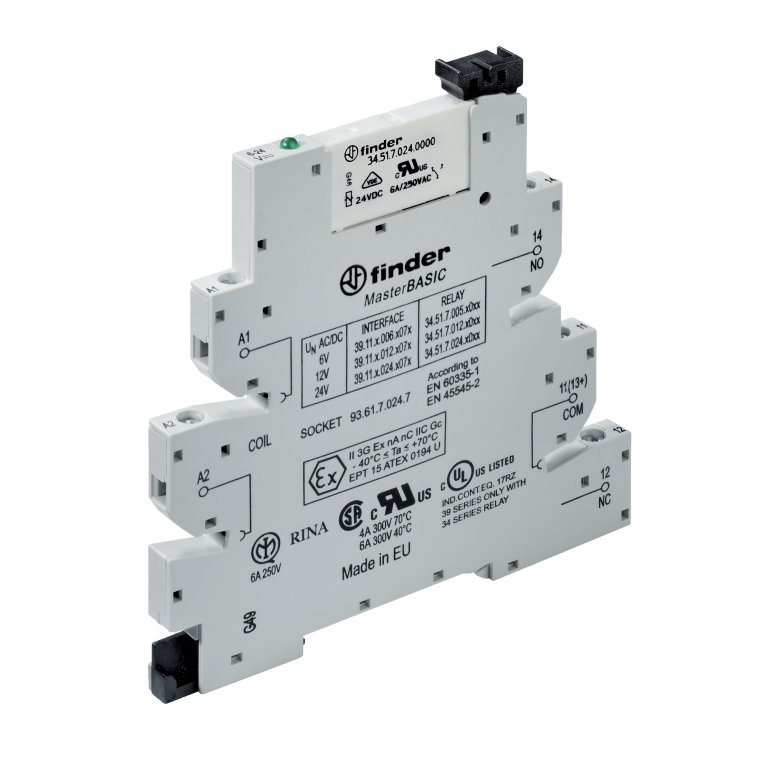

39 Series

Challenge ‘Space’ – Control of loads with minimum panel footprint.

Accomplished – Quick and easy interfacing to PLC outputs all in a 6.2 mm space saving package. Variety of options possible with EMR or SSR switching up to 6 amps and screw or push-in termination. You choose your slim-line solution.

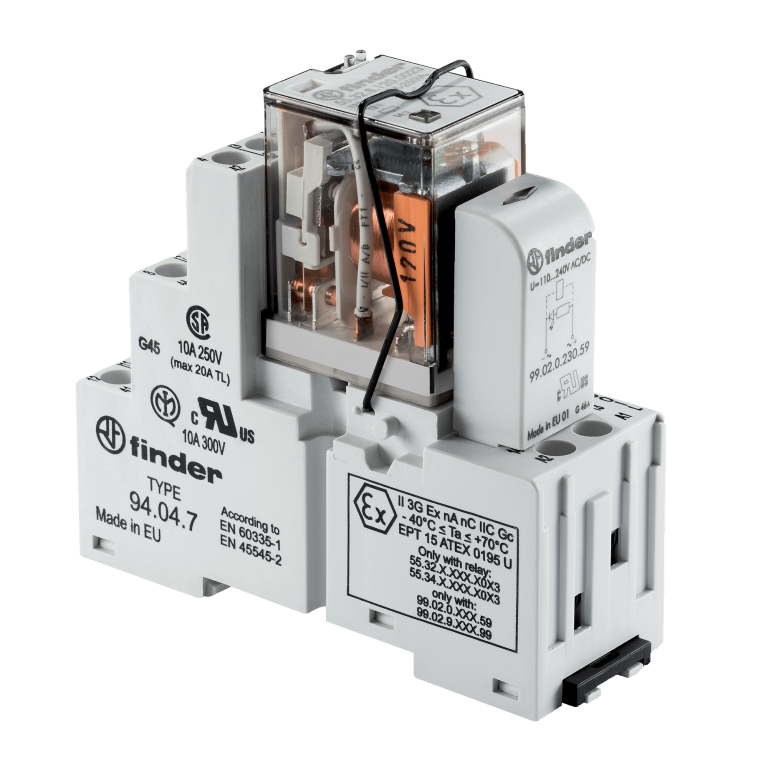

58 Series

Challenge ‘Contact Sets’ – Multi-pole configuration in cost-effective packaging.

Accomplished – Both 2 and 4 pole versions expanding capabilities while keeping the solution simple and cost effective. Manage current demands up to 9 amps (2 pole) with various terminations, suppression and LED options plus a hold down clip.

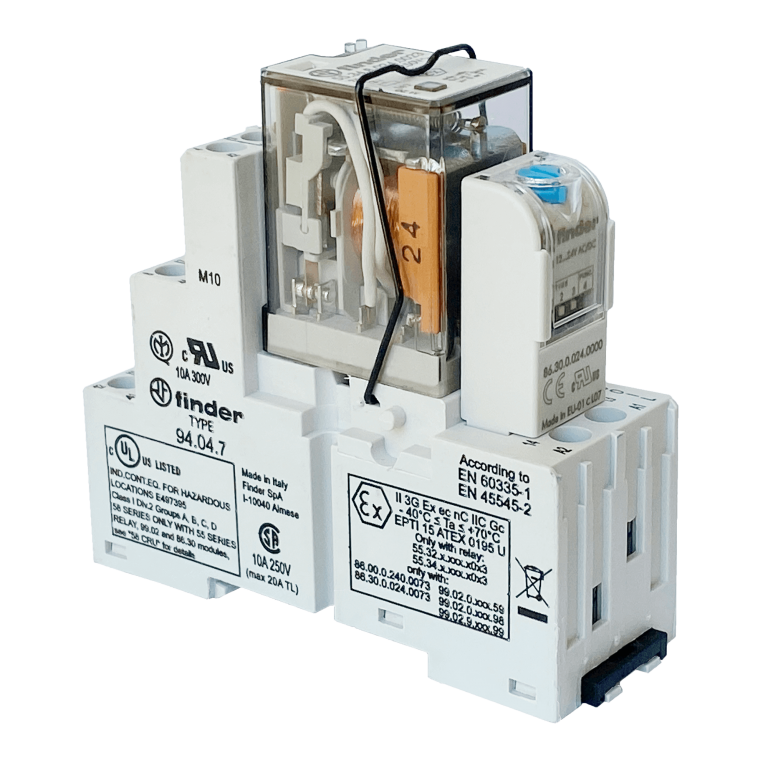

58 Series

Challenge ‘Time’ – Handle simple timing requirements.

Accomplished – No need to go large taking up space. The 58 Series is available as a timing interface module providing a simple solution to various timing needs (12 – 24 V AC/DC coils). Simple adjustment via front dip switch and top mount dial.

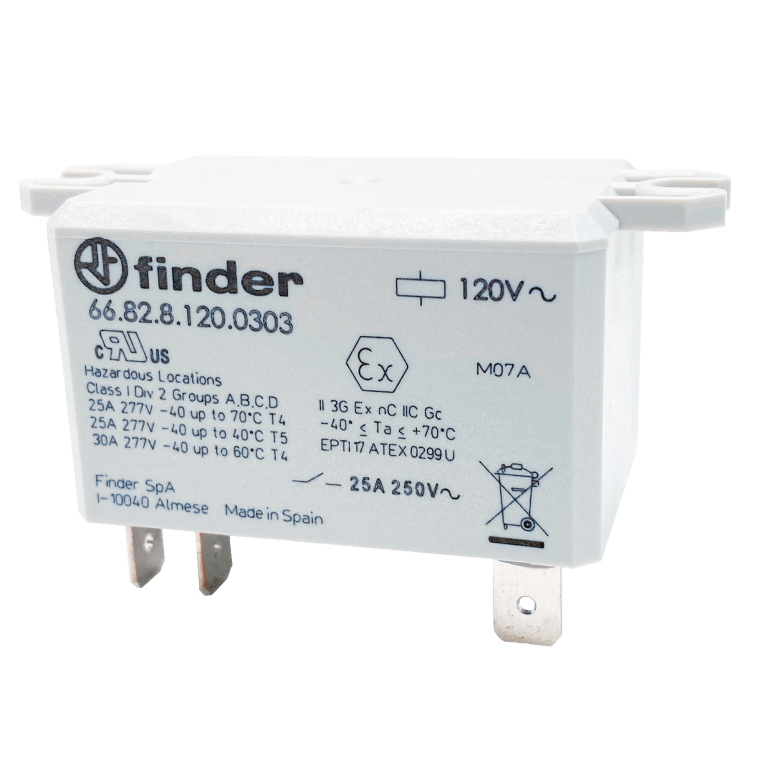

66 Series

Challenge ‘Power’ – Control of motor and solenoids.

Accomplished – With freon removed from many markets, solutions may use an explosive gas. To keep dimensional space small and offer enough power to switch compressor loads look towards the 66 Series. Up to 30 amps with panel or PCB mount.