Compact force guided interface modules

Multiple solutions for multiple applications

When considering machinery where safety is a factor, engineers need to consider all aspects of design. Standard products for day-in and day-out applications are usually changed for special construction products to meet these needs. From conveyors to gates and elevators, lifts, cranes, and presses there are many options to choose from.

Safety modules, controllers, expansion modules – all play a part depending on the type of machinery and application. If we look at our 7S Force Guided Relay Modules, approvals are higher with SIL 2 (PL d) or SIL 3 (PL e) for building to NE 62061 and IEC 13849-1. This series offers FGR solutions for many contact configurations under these ratings, but what if the application need was not to this level?

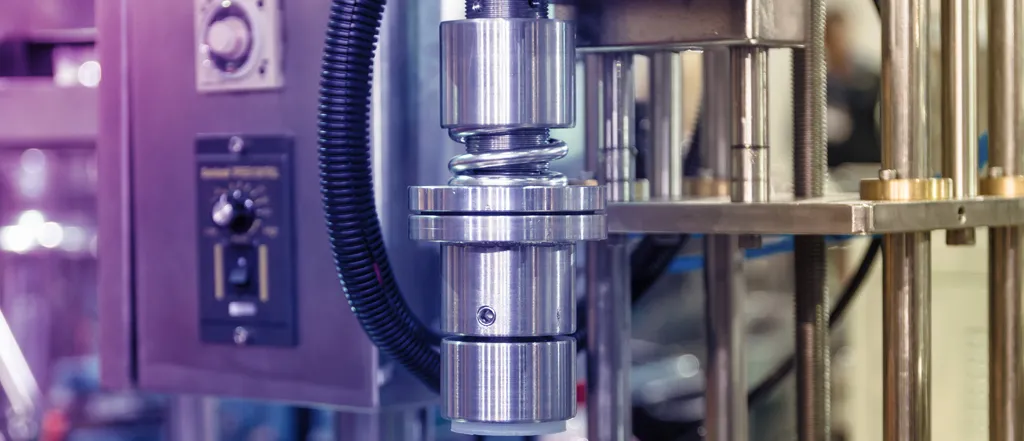

Enter the 48.x2 force guided interface modules

There are applications out there where a force guided relay is needed but not to the level of SIL 2 or SIL 3. A simple configuration of 1 NO and 1 NC contact is all that is required. What options does a designer have to offer a solution to meet say EN 61810-3 Type B needs?

Can we save some space and costs when considering these types of applications? Here is where the 48.12 and 48.P2 Force Guided Relay Interface Modules come in.

Features

• DPDT 8A

• screw or push-in termination options

• UL Listed

• approvals to EN 61810-3 Type B*

• 12 or 24 V DC coils

• AgNi + Au Contacts

* for EN 61810-3 only 1 NO and 1 NC. Shall be used as force guided contacts.

At the heart of the 48.12/P2 assembly, is Finder’s 50 Series relay. An 8 A, DPDT relay configuration with force guided contacts. The 50 Series relay is constructed with sets of linked or forcibly guided contacts. For the interface assemblies, Finder utilizes a silver-nickel base with a galvanic hard gold plating for the contacts. The gold contacts reduce minimum switching load to 50 mW, 5V and 2 mA and with gold impervious to influences of industrial atmospheres, provides a great solution for low level and infrequent switching.

Check out Finder’s 48.12/48.P2 Series for all your machine safety relay needs.

Resources

Book a Finder-15 Video Sales Call to discuss our machine safety products in detail.