Update your design with the 7S force guided relay module!

There are various levels of machine safety and approach to system designs. Some of these often include PCB force guided relays and a separate socket used as expansion relays. Modified from standard PCB relays, they offer solutions for various machine safety applications.

These applications are diverse including elevator lifts, CNC machines, conveyors and die stamping presses. Panels can vary from a few to many depending on the application needs.

Past options have potential for design and installation issues. Sockets may not be IP20, wiring is near the DIN rail and PCB pins could bend if not properly inserted. Is space left in between to allow access for the relay and wiring? Now imagine the time to trouble shoot a completed machine with say 20 of these. Is it wiring or a bent PCB pin? Which one? With designs progressing is the above the best approach or is there a more efficient, effective, and modern option improving solutions for today’s world?

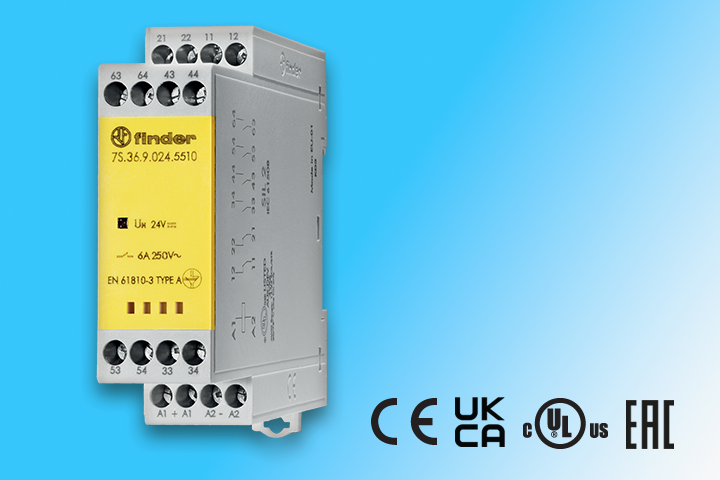

Finder’s 7S Series modular relay with forcibly guided contacts presents the solution.

THEN

- old PCB and socket 2–piece construction

- increased panel width (6 poles)

- wiring at base of socket

- increased assembly / install time

- risk of bent pins adding to inspection time

- lack of approvals limit use

NOW

- one piece direct to DIN

- narrow 17.5 (2+1) or 22.5 mm housing

- top wiring not base wiring

- screw or screwless solutions

- optional bracket for panel mount

The 7S Series keeps this simple. One piece, wiring at the top and screw or screwless termination to meet more of today’s panel demands. Easy installation, side by side stackable and easy to wire – effortlessly upgrading systems. With one part to procure, expanded approvals with SIL 2 PL d, and if needed SIL 3 PL e options, Finder’s 7S simplifies the approach.

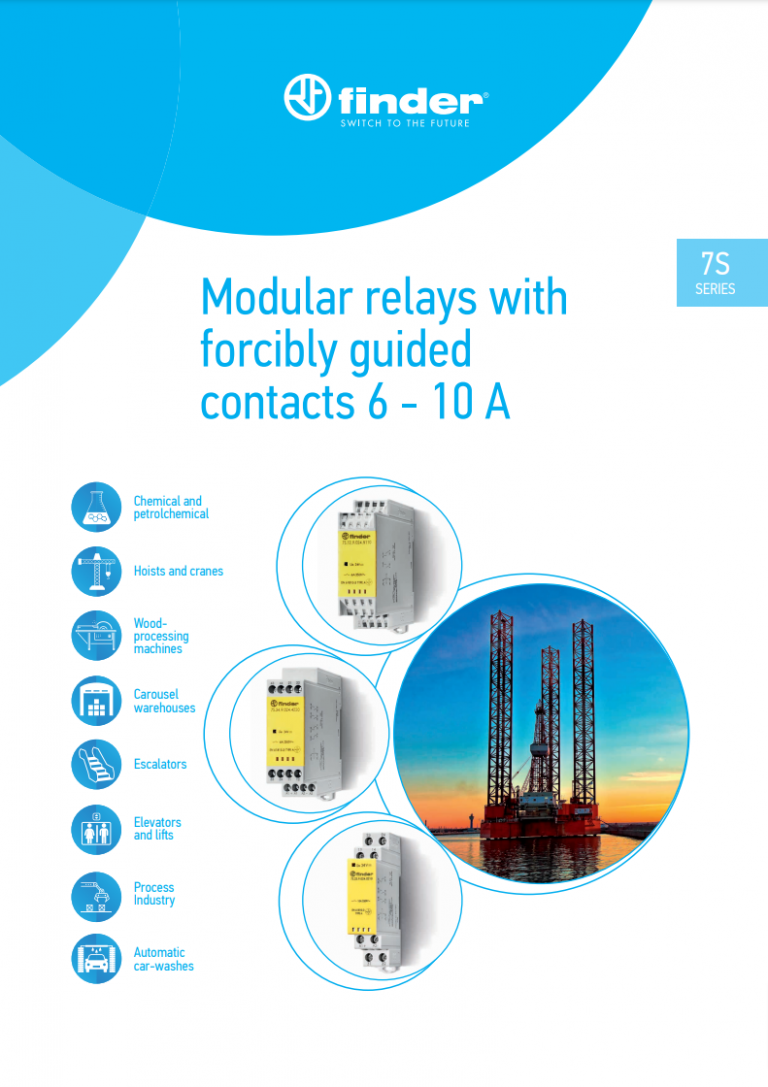

With over 50 different solutions available, a broad ambient temperature range from (– 40 … +70)°C and (6 … 10)A contact ratings, the 7S offers the below contact configurations.

SIL 2 / PL d

- 1 NO + 1 NC

- 2 NO + 2 NC

- 4 NO + 2 NC

- 2 NO + 1 NC

- 3 NO + 1 NC

- 5 NO + 1 NC

SIL 3 / PL e

- 2 NO + 1 NC + 1 AUX

For more information, click this link:

Modular Relays with Forcibly Guided Contacts

The 7S Series, simple, modern, convenient – a welcome addition to your machine safety needs.